Is it safe to run a generator out of gas

No, it is not safe to run a generator out of gas. Doing so can cause engine damage, overheating, and potential fire hazards. Always ensure

No, it is not safe to run a generator out of gas. Doing so can cause engine damage, overheating, and potential fire hazards. Always ensure

Key Takeaways Consider purchasing a generator that fits your power needs, as more powerful generators tend to be louder. Face the generator exhaust pipes away

Key Takeaways Conducting a basic check-up, such as checking the oil level, fuel valve, and choke, can help troubleshoot issues with the generator. Stale fuel

Key Takeaways Changing the oil in your generator is important for regular maintenance and will help ensure that it is a dependable companion. Make sure

Key Takeaways Since propane does not deteriorate, propane-powered generators last longer than gas-powered ones. Propane generators are more difficult to fix on your own due

We Got The Best One For Your Need Check List Find From Our Directory Top Model & High Quality Inverter Dual Fuel In a hurry?

Generator backfiring is a problem that occurs when the generator produces loud banging or popping noises and may also result in reduced power output and

Paralleling generators involves synchronizing the generators to operate at the same frequency and phase and then connecting them together using the correct wiring and cables.

Yes, non-inverter generators can be run in parallel with other non-inverter generators. However, not all non-inverter generators are capable of being run in parallel. This

A generator can’t run without a battery. Key Takeaways Most generators use a small battery to provide the initial spark to start the engine. As

What is a dual-fuel generator? A dual-fuel generator is a type of generator that can run on either gasoline or propane gas. This allows users

Yes, dual fuel is worth it on a generator. It allows you to use two different types of fuel (such as gasoline and propane) in

A generator is a machine that converts mechanical energy into electrical energy. Generators are used in power plants to generate electricity. The generators are driven

Maximizing Power Efficiency: A Comprehensive Analysis of the Best Dual Fuel Generators on the Market Overall Best Champion 200988 4.7/5 Peak: 4500W Gasoline, 4500W

If you have to use a generator for an extended period of time, you need to make sure it is properly set up. One of

Bluetti Portable Power Station AC200p Review We tested with 12V Freezer for 26 hours Complete Overview of Bluetti AC200P If you’re looking for a power

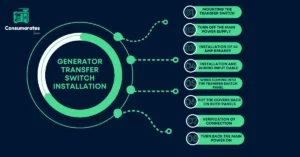

How to Install Transfer Switch on a Generator: 8 Steps to Follow A power failure is probably the last thing we want to encounter. It’s

You’ve heard the news, and you know it’s coming: there’s a hurricane on the way, and it could be bad. You prepare your home as

If you are in the market for a new generator, you might be wondering what is the best generator type to buy: an inverter generator

If you have an RV then it is important to understand how electricity works in your home as well as in your RV. When you

Beginner Guide From Consumarates Review, News & Market What can a 10000 watt generator run Learn more How to make a 50 amp generator cord

10000 Watt Generator A complete Buying Guide *** Overall Best *** WESTINGHOUSE WGEN15000DF 5/5 Peak: 15000W Gasoline, 13500W Propane Running: 12000W Gasoline, 10800W Propane

Remote Start Generator Unlike many homeowners, you may never have given much thought to the possibility of a power outage. But what would you do

Best Quiet Generators to buy in 2023 – (Under 59 dB) Quiet generators are often designed to be energy-efficient, resulting in lower fuel consumption and

What is an inverter generator? An inverter generator is a type of portable power generator that turns the direct current (DC) electricity from its battery

Best Inverter Generator to Buy in 2023 All Rounder WESTINGHOUSE IGEN4500DF 5/5 Peak: 4500W Gasoline, 4050W Propane Running: 3700W Gasoline 3300W Propane Weight: 104.7

Key Takeaways Low oil levels in the engine can also prevent the generator from starting, check the oil levels and refill if necessary. Dead battery

Like most homeowners, you probably wouldn’t think twice about storing a generator in your backyard. After all, generators are usually small and light enough to

Generators have come a long way since their humble beginnings as simple machines used to power small businesses and homes. Today, generators are reliable sources

Most people rely on electricity to power their homes, which can be a significant inconvenience when the power goes out. If you live in an

Are you prepared for a power outage, but terrified by the thought of your trusty generator turning into a ticking time bomb? Fear not! In

How One Generator Made Dreams Come True: WEN 56380i Generator Review Are you looking for a combo package? If you are looking for a portable,

Generator For Apartment (5 Picks) How we picked Solar and battery-powered Our top picks are eco-friendly, using solar and battery power to keep your apartment

Inverter technology produces electrical power with little total harmonic distortion (THD), allowing you to use delicate electronics like cellphones, laptops, and TVs worry-free. A dual

Are you looking for a generator that can provide the power you need for your home or small business in case of an outage? If

Are you looking for an easy-to-use, reliable portable generator? If so, the Westinghouse iGen2500 could be the perfect fit for you. This generator is designed

The Briggs & Stratton P4500 is an excellent choice for those who need a reliable and durable portable generator. It is perfect for use in